ElectraMate A Class

ElectraMate Group is a specialist provider of technical services to homeowners, housing associations, registered charities, local authorities and businesses across the south of the U.K. Open vented thermal store repairs from the UK’s leading experts.

The Technological Leap in Central Heating and Water Storage Solutions

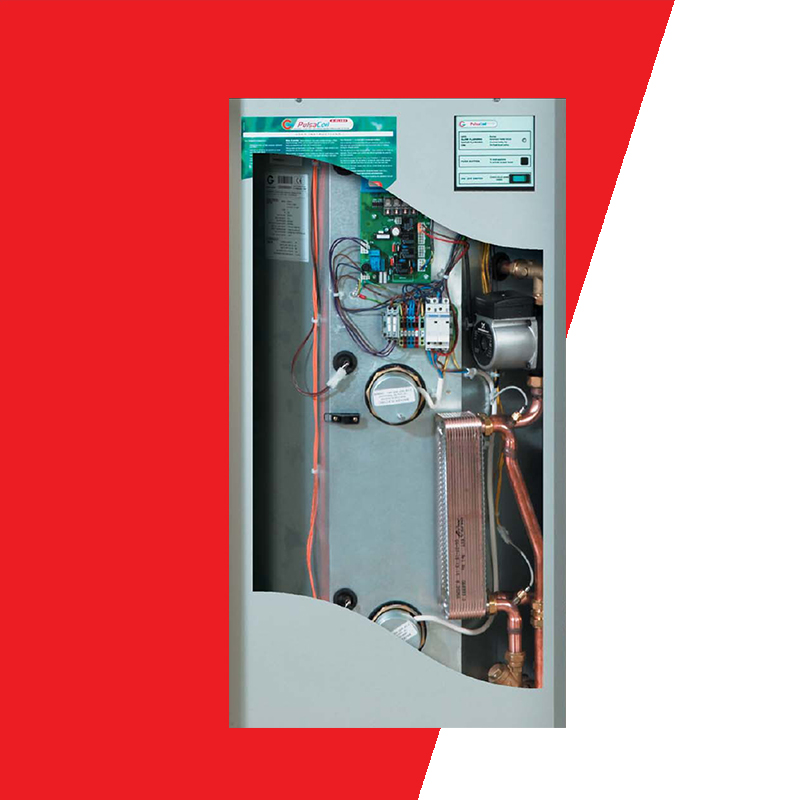

The Gledhill ElectraMate A Class had been established as the undisputed no1 solution for apartment buildings for over 7 years. An electrical appliance that could supply the benefits of mains pressure hot water with wet central heating while making the most of off-peak tariffs and yet require no pressure or temperature relief runaways, it saved tens of thousands of pounds in ducting costs alone.

The ElectraMate A Class

A Comprehensive Overview

All the proven benefits of Thermal Storage

- Ultra-high performance providing instantaneous hot water and heating

- The ability to save up to 15% on fuel bills

- ‘Power Shower’ pressures for every shower in the home

- The ability to take a bath, a shower, and run hot water all at the same time with no loss of heat or pressure

- Dry roof space with no tanks or pipes in the loft, so no need to worry about freezing pipes in the winter

- High-quality water at every tap

- Balanced pressure to all terminal fittings

- Because the immersion elements are situated in the same primary water all the time and this water is not renewed, no scaling takes place, even in hard water areas.

- Secondary supply tank

- Ball valve

- Warning pipe

- Pressure-reducing valve (under 8 bar)

- Separate external expansion chamber

- Shower pump – thanks to excellent hot water performance

- Smaller diameter supply pipes

- Simpler terminal fittings including mixer taps

- Sophisticated shower valves

- High-pressure showers

Plus the Evolutionary benefits of ElectraMate A Class

- The ability to make the most of off-peak tariffs

- Lower running costs than dry storage radiators and off-peak hot water storage

- Only one energy supply to the property required

- No flueing problems.

- The need for annual boiler servicing is eliminated.

- Capital cost is comparable to other systems when the simplified energy supply is taken into account.

- A responsive radiator and high-performance hot water system.

- Provides over 35 L/minute

- Water is controlled at 55°C at the taps (or lower if required)

- Heating is provided at normal design temperatures (or lower if required)

Revolutionary Design Provides Mains Pressure Hot Water And Wet Central Heating At Off-Peak Rates

The innovative new ElectraMate A Class offers significant benefits over ordinary systems

- Extra High Hot Water Flow Rates

- No Need for In-Line Scale Inhibitor

- No Need for Pressure Reducing Valve

- No Need for Non-Return Valve

- Water is pumped over the immersion elements whenever they are providing heat to minimize “kettling”

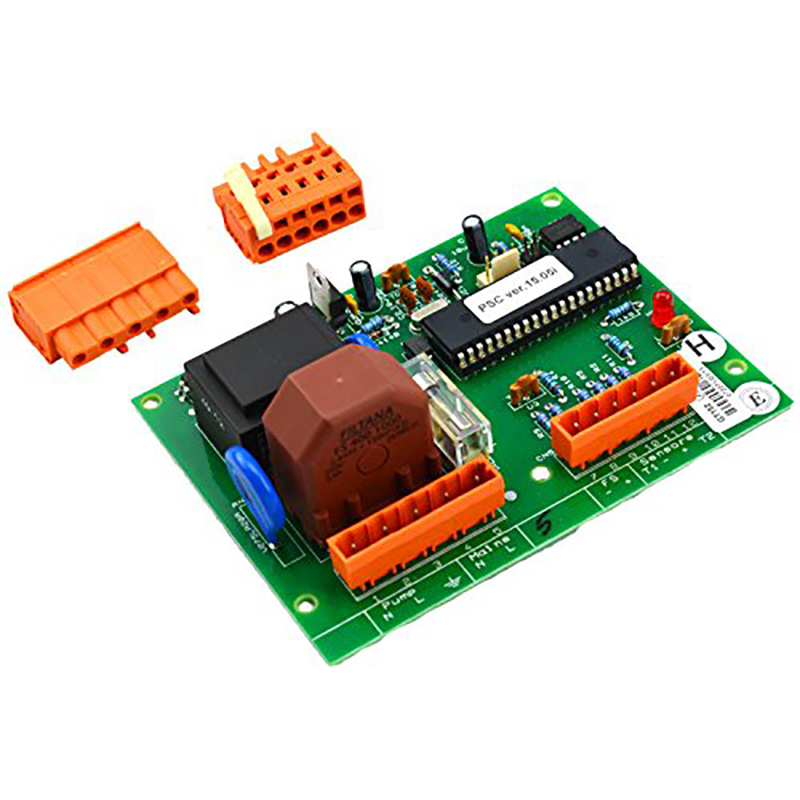

- The thermal store and heating circuit operate as a sealed primary system.